Are you trying to name that rubber guard on a boat's edge? Using the wrong term leads to confusion and costly ordering mistakes. Let's clear it up.

The rubber protection around a boat is most often called a fender, bumper, or rub rail. These parts come in various profiles, such as D-type, square, or cylindrical, and are designed to absorb impact and protect the boat's hull from damage during berthing or alongside other vessels.

Now that you know the common names, let’s look at the different types you might see. Understanding the specific terms is crucial because the name often tells you about its shape, how it's made, and its best use. Getting this right helps you choose the perfect protection every time.

What is the rubber strip around a boat called?

Have you seen those long rubber strips on workboats1 and wondered about their exact name? Just calling it a 'rubber strip' isn't precise enough for a technical order.

The long rubber strip found on many boats is commonly called a D-type fender2 or simply a D-fender3. It gets its name from its D-shaped cross-section. This type is extremely popular for tugboats4, workboats1, and even loading docks for continuous and reliable protection.

Let's dive deeper into why this type is so common. The "D" shape isn't just for looks; its flat back makes it easy to install directly onto a boat hull or a jetty face, while the curved front provides an excellent surface for absorbing impact energy. It's a simple, effective design.

Most of these long, strip-type fenders are made using a process called extrusion5. This is where we push heated rubber through a shaped die, kind of like squeezing toothpaste out of a tube. This process allows us to create very long, continuous pieces without joints, which is perfect for lining the entire side of a vessel.

I remember helping a client like Tommy who needed a unique profile for a new fleet of pilot boats6. We designed a custom die, and because extrusion5 tooling is simple and cheap, we went from design to production in just a couple of weeks. If we had tried to use molding, the cost and time would have been far too high.

Here’s a quick comparison of the two manufacturing methods for strip fenders:

| Feature | Extrusion Process | Molding Process |

|---|---|---|

| Length | Can be very long (e.g., 20+ meters) | Limited by mold size (usually under 3 meters) |

| Tooling Cost | Low | High |

| Production Speed | Fast, continuous | Slower, batch by batch |

| Material Quality | Often requires higher-grade rubber | Can use lower-grade compounds to cut costs |

| Custom Shapes | Easy and inexpensive to customize | Difficult and expensive to customize |

What are the rubber bumpers on boats called?

Do you just call them 'bumpers' but suspect there's a more professional term? You're right to be careful. While 'bumper' is understood, using the industry term prevents mix-ups.

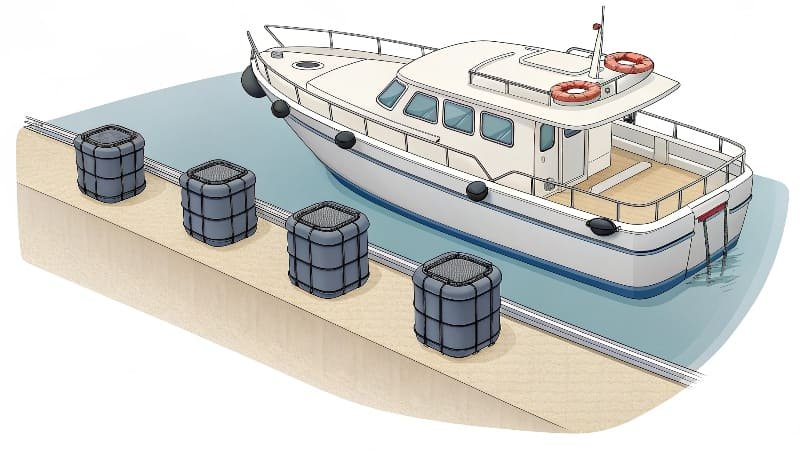

In the marine industry, the rubber bumpers on boats are professionally called "fenders." This term covers a wide range of products, from simple rubber blocks to highly engineered systems. The specific type is then identified by its shape, such as Cylindrical Fender or Square Fender.

The term 'bumper' is very general, but 'fender' is the standard in the maritime world. When you say fender, people in the industry know you're talking about a device designed to absorb the kinetic energy of a berthing7 vessel.

So, why are there so many different shapes? It all comes down to the application.

Common Fender Types

- Cylindrical Fenders8: These are one of the simplest and most economical types. They are often seen on docks and are great for a wide range of vessel sizes. Their round shape works well even with large changes in water level.

- Square Fenders9: These are similar to D-fender3s but with a square or rectangular face. They are very tough and are often used in demanding environments like tugboats4 or as rub rail10s.

- Arch Fenders11: These have a V-shape and are known for their high energy absorption12 and low reaction force13, making them a very popular choice for general-purpose berths.

The manufacturing process also plays a big role. While long strips are extruded, these individual 'bumper' style fenders are typically made through compression molding14. In this process, a specific amount of rubber compound is placed into a metal mold, which is then heated under pressure. This forces the rubber to take the shape of the mold and vulcanizes it, making it strong and durable. While effective, this process is slower and mold-intensive compared to extrusion5.

What is the floating ring on a boat called?

Ever seen someone toss a ring-shaped object from the shore or a boat during an emergency? It's easy to mistake it for just any floating ring, but it has a very specific name.

The floating ring on a boat is called a lifebuoy or life ring15. It is a critical piece of personal safety equipment designed to be thrown to a person in the water to provide buoyancy and prevent drowning. It is not designed to protect the boat itself.

Let's be very clear here: a lifebuoy16 is for saving people, not protecting property. Mixing it up with a fender could have a tragic outcome. A fender is made of dense, heavy rubber designed to absorb huge impacts. A lifebuoy is made of lightweight, buoyant materials like polyethylene or PVC, filled with foam to ensure it floats high in the water and is easy for a person to grab.

I cannot stress this enough. In my years in the industry, I've seen all sorts of equipment on vessels, and safety gear is non-negotiable. Every piece has a purpose.

Here is a simple breakdown of the differences:

| Feature | Fender (Boat Protection) | Lifebuoy (Life Saving) |

|---|---|---|

| Primary Purpose | Protect the vessel hull from impact | Save a person from drowning |

| Material | Heavy-duty rubber | Lightweight plastic, foam |

| Key Property | Energy absorption, durability | Buoyancy, visibility |

| Typical Location | Attached to the hull or dock | Stored on deck in an accessible holder |

| Color | Usually black | Bright orange or white with reflective tape |

A fender is for the boat; a lifebuoy is for the crew. Both are essential, but they have completely different jobs. Always make sure safety equipment is clearly marked and ready for immediate use.

What is the ledge around the edge of a boat called?

That 'ledge' or raised edge you see running along the top of a boat's hull is a key structural feature. It does more than just look good; it has a very practical purpose.

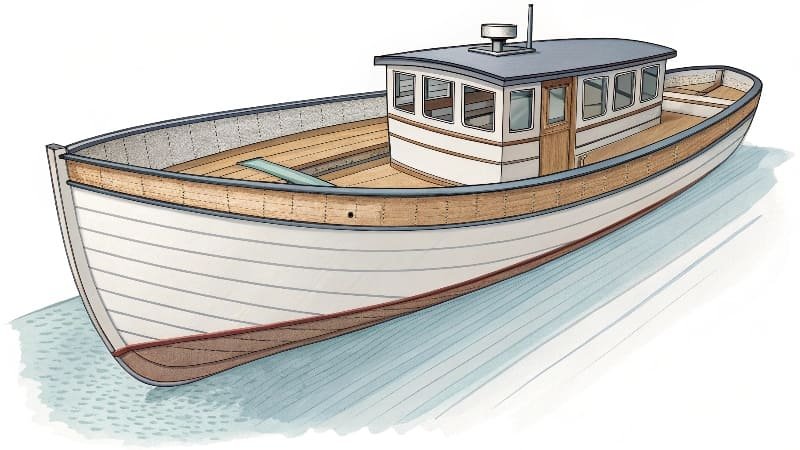

The ledge around the top edge of a boat's hull is called the gunwale17 (pronounced 'gunnel'). On many smaller boats and workboats1, this gunwale17 is often capped with a protective rubber or PVC strip, which is called a rub rail10 or gunwale guard18ps://www.discoverboating.com/resources/gunwale-on-boat)17 guard.

The gunwale is the top edge of the hull, providing structural strength and a point to attach things like railings and cleats. However, because it's the widest part of the boat, it's also the most likely part to make contact with a dock, another boat, or a piling. This is where the rub rail comes in.

A rub rail is essentially a type of fender designed specifically to protect the gunwale17. It acts as a sacrificial bumper, taking the scrapes, bumps, and impacts that would otherwise damage the hull's fiberglass or paint. These can be simple, rigid PVC strips or more robust, shock-absorbing rubber profiles.

The choice of material and shape depends entirely on the boat's use.

- A small recreational boat might use a light PVC insert for aesthetics and minor scrape protection.

- A heavy-duty workboat or pilot boat will use a thick, durable rubber rub rail—often an extruded D-type or similar profile—to handle repeated, forceful impacts without fail.

In my work, I've supplied countless meters of extruded rubber profiles to boat builders for exactly this purpose. They give me the boat's gunwale17 design, and we select or create a profile that fits perfectly and provides the level of protection they need. The rub rail is the boat's first line of defense.

Conclusion

In short, the rubber part on a boat is usually a fender or rub rail. Knowing the specific type—like D-fender3 or lifebuoy16—ensures you get the right product for the job.

Get practical guidance on selecting robust rub rails and profiles that survive daily bumps and abrasion. ↩

Learn where D-type fenders excel, typical sizes, mounting options, and performance so you can spec a profile that truly protects your hull. ↩

See datasheets and selection guides to match D-fender hardness, dimensions, and curvature to your vessel’s operating conditions. ↩

See proven configurations and materials that withstand push-pull work, corner hits, and continuous service. ↩

Explore the extrusion process, die design, and continuous-length advantages to cut tooling costs and lead times. ↩

Explore case studies showing how profile choice improves boarding operations and protects hulls in frequent contact. ↩

Improve docking safety with procedures, approach angles, and fender strategies that minimize collision damage. ↩

Get application tips, diameter ranges, and installation layouts to ensure reliable protection across changing water levels. ↩

Understand load distribution, corner protection, and toughness to decide if square profiles fit your heavy-duty use case. ↩

Compare PVC vs rubber rub rails, installation methods, and durability to prevent costly hull scuffs and dockside damage. ↩

Review performance curves and case studies to balance high energy absorption with low reaction forces at your berth. ↩

Understand test methods and KPIs so you can compare fenders by absorbed energy per deflection and pick the right rating. ↩

Learn how lower reaction forces protect structures and how to read performance curves on spec sheets. ↩

Learn cycle steps, material choices, and mold design factors to select the right manufacturing route for your fender. ↩

Access safety best practices for storage, throwing techniques, and inspection intervals to improve emergency response. ↩

Confirm buoyancy, visibility, and retroreflective requirements so your safety gear is legal and ready to save lives. ↩

See diagrams and structural explanations to understand why protecting the gunwale preserves your boat’s integrity. ↩

Find installation guides and product options so you can add long-lasting protection to high-contact hull areas. ↩