Marine Fenders

Types, Applications & Selection guide

Jettyguard is one of the leading Marine Fender manufacturers & suppliers, based in China, we offer a wide range of marine fenders and mooring systems.

Our company can offer custom marine fender system according to your requirement too.

Contact us for more information or request a full product categolue.

What are Marine Fenders?

When a large vessel or even a boat approaches to a dock or a bridge. If nothing is present to cushion the impact, disaster can be the result. That’s when marine fenders come in.

Essentially, marine fenders are energy-absorbing protective barriers, they mitigate energy due to ship impact during mooring and berthing.

They act as a cushion between the ship and structures like quay walls, bridges, offshore platforms or other vessels in an effort to avoid damage on both parties.

Think of them as the marine bumper systems. But unlike car bumpers, most of the marine fenders are built to handle forces that can exceed kilonewtons—enough to crack concrete or bend steel if left unchecked.

While they do look simple in appearance—tends to be a block of rubber or foam—they’re in fact heavily engineered products. Made from such materials as rubber (for hardness and durability) and EVA foam (for lightness and flexibility), such fenders are designed to survive harsh marine environments like saltwater, sunlight, and heat.

Their Contribution to Maritime Activity:

Marine fenders are utilized wherever vessels and port infrastructure protection are required. A cargo vessel unloading into a harbor, a yacht moored at a marina, a LNG distribution vessel calls offshore fender solutions – they all depend on the use of fenders for a smooth, safe, damage-free operation.

They’re not merely security, though. Marine fenders also play a key role in vessel and infrastructure maintenance and efficiency—reducing downtime for repairs and allowing ships to berth quickly and safely.

Continue reading for the critical part you need to know about Marine Fenders…

REQUEST A QUOTE FOR MORE DETAILS

Practical Guide to Marine Fenders

Common Applications of Marine Fenders

Vessel Protection (Big Ships to Small Boats)

Installed on vessels to absorb impact energy during docking and mooring.

Commercial Ports and Terminals

Protect quay walls and berthing vessels from impact forces.

Offshore Floating Structures

Absorb energy during vessel-to-structure interactions, such as FPSOs and floating docks.

Shipyards and Dry Docks

Prevent damage to vessels during docking and undocking operations

Bridge piers

Protect bridge supports from vessel collisions and tidal forces

Inland Waterways and Marinas

Protect smaller vessels and recreational boats in low-energy environments

How do Marine Fenders work?

When a vessel berths or moors, it generates kinetic energy. Marine fenders step in to absorb this energy, reducing the force transferred to the vessel and the structure. Take them as shock absorbers: they are compressed or deformed by impact, then they’ll bounce back to their original shape and be ready for the next encounter.

Why Are Quality Marine Fenders Essential?

Marine fenders are not just “marine bumpers”—they are engineered lifelines that defend against catastrophic losses. Their obvious and basic benefits from them are:

Avoid Damages to Vessels

Poor quality fenders may fail to protect ships from impacts, leading to costly repairs

Prevent Structural damage

Inadequate fenders can result in damaged dock structures, impacting port operations and safety

Reduce maintenance frequency

Poor quality fenders may fail to protect ships from impacts, leading to costly repairs

At Jettyguard, we have personally observed the consequences of compromising harbor fender systems, which can result in dock damage, vessel repairs, environmental liabilities, and even business failure.

Although the competition in the market has led to unhealthy quality compromise everywhere, the bottom line shall be stuck to for those businesses seeing the long term.

The more critical impacts of the quality marine fenders that are often overlooked are

Provide Guardians of Safety

- Your Liability Firewall

Critical Risks of Subpar Rubber Fender

- Lawsuits from the authority on docking fender failure

- Structural Damage: Weak energy absorption results in weak protection to the fender support structure in an unusual berthing operation.

- Regulatory Blowback: Non-PIANC-compliant systems void class approvals, halting project handovers

Ensure Long-Term Business Protection

- Reputation = Currency

We’ve seen that when documentation-approved quay wall fenders are tested on site and fail to meet promised energy absorption capacity, it can cause:

- Bankrupt and shut down of business due to quality failure on large replacement.

- Long delay of the project handovers with huge compensation accordingly.

- Permanently removed from the bidding for future tenders.

Avoid The Silent Profit Killer

- Project Finance Risks

Say no to manipulated quality measures

When substandard fender systems are questioned on site:

- The cost to fix it can be tripled to no ceiling than it can be before delivery

- Delays in payment collection and penalties create unnecessary financial risk and stress

Say No to unqualified Engineering

- Inadequate engineering leads to solutions that save costs and win for the project in the short term but fail in operation, which causes way larger losses and dangers for every party involved.

Prevent Hidden Costs for authority

- The Illusion of "Savings"

| Cost Factor | “Cheap” Fenders | Quality Fenders |

|---|---|---|

| Initial Cost | $84,000 | $138,000 |

| Year 1-5 Repairs/Replacement | $220,000 | |

| Vessel Damage Claims | $410,000 | $0 (insurance waived) |

| Oper. Downtime Days | 27 | 0 |

| Total 5-Year Cost | $714,000 | $138,000 |

Why Choose Jettyguard?

At Jettyguard, we don’t just make or supply marine fenders—we redefine reliability. While others claim industry compliance, we go further by combining technical mastery with supply chain transparency. Here’s why you can depend on us.

1. 40+ years Manufacturing-based Expertise

From rubber fenders, EPDM-SBR composites, to EVA foam core with SPUA cover, we offer every fender type, size, and material grade to meet PIANC 2002, BS 6349:4, and EAU 2004 standards.

From simple fender piles to systematic fender structures, our certified welders realize the design with techniques and wisdom.

2. Testing Practices You Can Trust

2,000-tonne compression testers and rubber specimen testing equipment ensure every batch of rubber output—with practices proven to be consistent.

Get certified test reports without manipulation of the testing operation.

2. Engineering Excellence Built on Industry Secrets

Our engineers don’t only perform berthing energy calculations and structural design calculations, but also audit the fender factories to avoid flaws like substandard rubber blends or hidden cost-cutting tactics.

When designing fender systems, we preempt risks from rubber compounding to transportation details—solutions rooted in our 40+ years of tracking experiences.

4. Supply Chain Mastery, Not Guesswork

We know which factories alter filler ratios to cut costs or misrepresent energy absorption metrics. This lets us handpick partners for true reliabilities.

Our supplier prequalification system and quality control measures ensure traceable raw materials and manufacturing practices

How to Select the Right Marine Fenders?

Easy steps to find out your ideal marine fender type.

1. Applications of Marine fenders

Find out what and where needs to be protected.

Scenario Matching → Direct Access to Product Lines

| Application Scenario | Key Requirements | Recommended Fenders |

| Large Vessel Berthing | High energy absorption; Safety; durability; | Rubber Fenders (Cone fender/Cell fender/Leg fender/Cylindrical fender/Arch fender) |

| Workboat operation (Fishing boats/Rescue boats/Pleasure boats) | Lightweight; UV resistance; Low maintenance | Foam boat fenders |

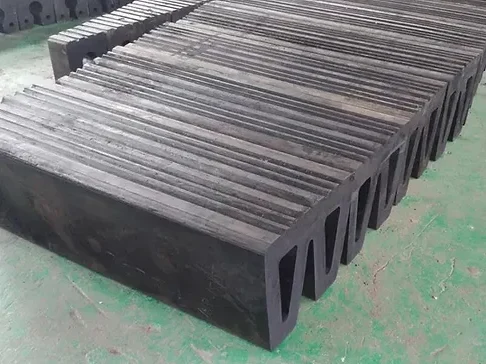

| Tugboat Operations (Tugs/Pilot Boats) | Abrasion resistance; Low maintenance | Workboat Fenders (M fender/W fender/Keyhole fender/tug cylindrical fender) |

| Floating Dock Protection | Lightweight; Corrosion-proof; | Foam Fenders (EVA foam/PU Coated) D fenders |

| Ship-to-Ship Mooring | Quick recover; High energy absorption; | Pneumatic Fenders |

| Navy port docking; Cruise vessel berthing | Surface protection; Abrasion resistance; High energy absorption | Foam-filled fenders (EVA foam) |

| Wide structure surface protection for small impact | Mass installation with low cost; Low maintenance; | D fenders |

2. Materials of Marine fenders

Material Comparison Matrix

| Property | Rubber Fenders | Foam fenders with SPUA Cover |

| Energy Absorption | ★★★★★ | ★★★★★ |

| Installation | ★★★☆ (Requires lifting gear and more complex assembling.) | ★★★★★ (Portable by hand or Easy hanging and Installing by shackle connection) |

| Weight | ★★★ | ★★★★★ (Lighter than rubber with same volume) |

| Shear Resistance | ★★★★★ | ★★★ |

Get an Offer that helps you Win!

For any projects or RFQs related to Fender system, mooring and structural steel solutions.

We are here to support.

Contact us now!