How Rubber Fenders Protect Vessels from Impact?

In the vast world of maritime engineering, some of the most critical components are also the most unassuming. Among these are rubber fenders, the robust cushions seen lining the edges of docks, ports, and vessels. While they may seem like simple rubber blocks, they are sophisticated engineering solutions designed to perform a crucial task: safely absorbing the immense kinetic energy of a moving vessel upon berthing. This article explores the science and mechanics behind how rubber fenders protect both multi-million dollar vessels and vital port infrastructure from damaging impacts.

The Core Principle: Energy Absorption and Force Reduction

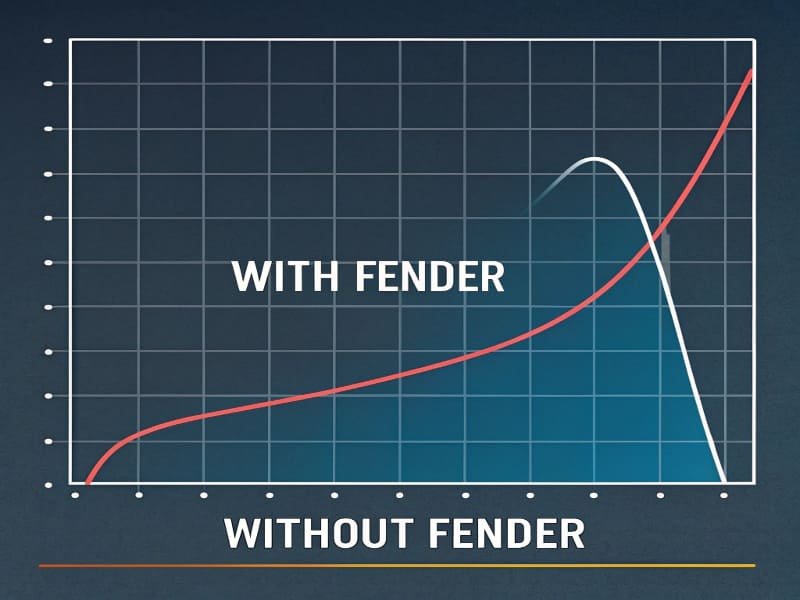

At its heart, a rubber fender's job is to manage energy. A vessel, no matter how slowly it's moving, possesses a significant amount of kinetic energy (E = ½mv²). When it makes contact with a stationary object like a quay, this energy must be dissipated.

Without a fender, the impact would be against a rigid, unyielding surface (e.g., concrete). This would cause the energy to be transferred over a very short time, resulting in an extremely high impact force. Such forces can easily cause structural damage, such as dents, cracks, or punctures to the vessel's hull and damage to the dock structure.

A rubber fender works by introducing a "cushioning" mechanism. It is designed to deform (compress) upon impact. This simple act of deformation accomplishes two primary goals:

- Extends Impact Duration: The fender increases the time over which the vessel's deceleration occurs. According to the impulse-momentum theorem (Force × time = change in momentum), if the impact time is increased, the peak force experienced by the hull and the dock is significantly reduced.

- Converts Kinetic Energy: The kinetic energy of the vessel is converted into potential energy stored within the compressed rubber. The fender then dissipates this energy as heat as it returns to its original shape.

Key Mechanisms of Protection

Beyond the core principle of energy absorption, fenders employ several mechanisms to ensure comprehensive protection.

1. Deformation and Reaction Force

When a vessel pushes against a fender, the fender compresses and exerts an opposing force, known as the Reaction Force. An ideal fender has a high Energy Absorption (EA) to Reaction Force (RF) ratio. This means it can absorb a large amount of energy while transmitting a relatively low force back to the vessel's hull. The fender's shape, material composition, and internal structure are all engineered to achieve an optimal performance curve (Energy Absorption vs. Reaction Force).

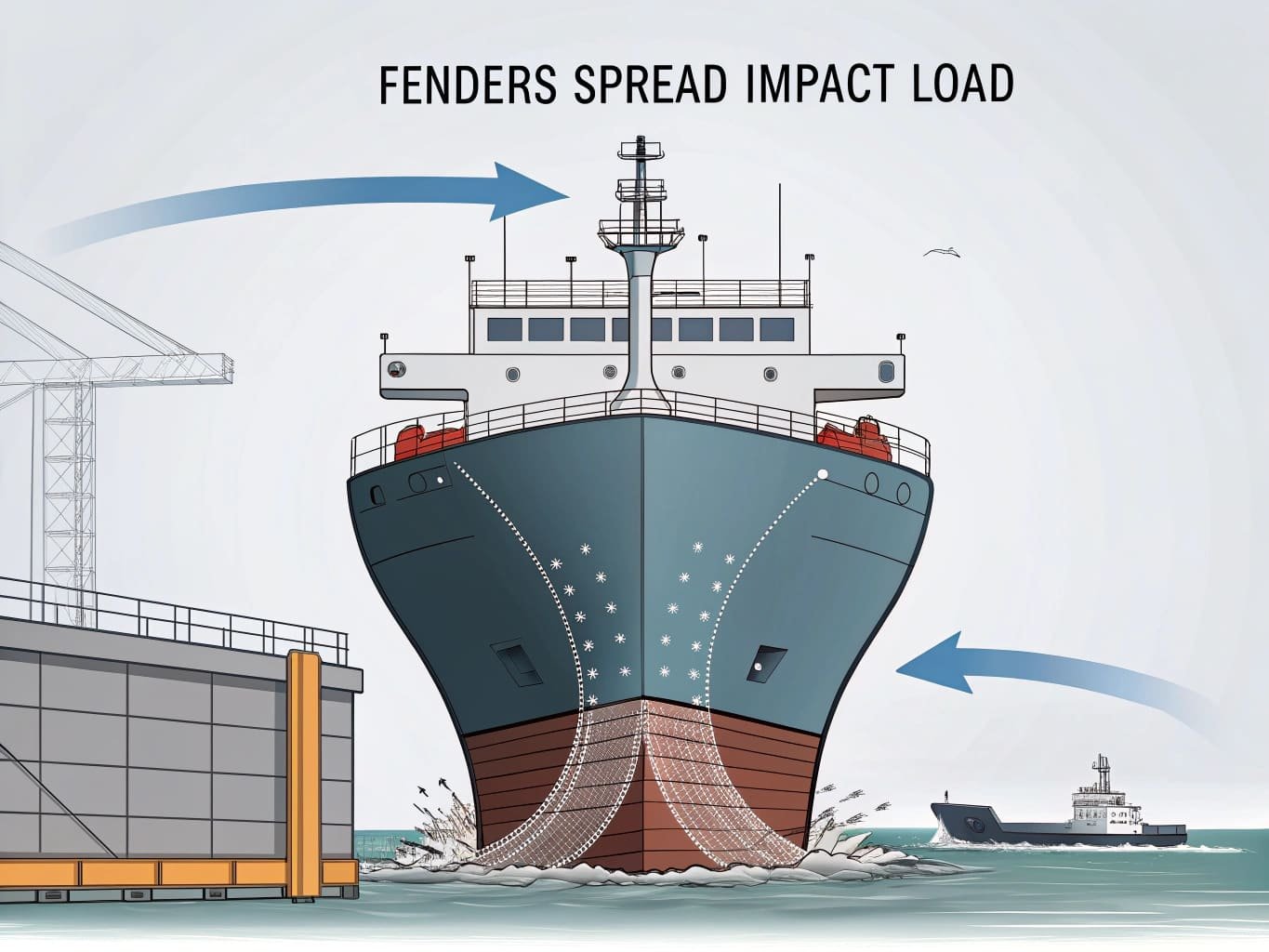

2. Spreading the Impact Load

A direct impact concentrates the entire force onto a small area, creating immense pressure (Pressure = Force / Area). This high pressure is what causes punctures and dents. Fenders, often used in conjunction with large steel frontal panels, distribute this impact force over a much wider surface area of the vessel's hull. By lowering the pressure at any single point, they prevent localized damage and protect the structural integrity of the hull.

3. Accommodating Angular Berthing and Movement

Vessels rarely approach a berth perfectly parallel. Fenders are designed to function effectively even during angular impacts. High-performance fenders like Cone and Cell types can maintain their energy absorption capabilities even at high berthing angles.

Furthermore, many fender systems are fitted with low-friction face pads, typically made from Ultra-High-Molecular-Weight Polyethylene (UHMW-PE). These pads allow the vessel to slide vertically and horizontally along the fender surface without inducing high frictional or shear forces, which is essential for accommodating changes in tide, loading conditions, and slight vessel movements caused by wind and currents.

Types of Rubber Fenders and Their Applications

Different operational needs require different types of fenders. The choice depends on factors like vessel size, berthing energy, and port structure. Below is a table summarizing some common types.

| Fender Type | Image (Illustrative) | Key Characteristics | Typical Applications |

|---|---|---|---|

| Cone Fender |  |

Very high energy absorption to reaction force ratio. Excellent performance at large berthing angles. Stable geometry. | Container terminals, bulk cargo berths, Ro-Ro ramps, oil and gas facilities. |

| Cell Fender |  |

Very high energy absorption capacity. Robust and reliable design. Good shear force resistance. | Oil terminals, bulk terminals, and container berths where large vessels operate. |

| Arch Fender |  |

Simple, rugged, one-piece design. Provides high durability and requires low maintenance. | General cargo berths, Ro-Ro terminals, and workboat harbors. |

| Cylindrical Fender |  |

Economical and easy to install. Can be mounted horizontally, vertically, or diagonally. | Small jetties, workboat harbors, and for protecting the bows and sterns of larger vessels. |

| Pneumatic Fender |  |

Floating, lightweight, and easy to deploy. Uses compressed air as the absorption medium. Ideal for variable tides. | Ship-to-ship (STS) transfers, offshore platforms, and temporary fendering needs. |

Conclusion

Rubber fenders are far more than just "bumpers" for ships. They are meticulously engineered safety systems that form the critical interface between a vessel and its berthing structure. By skillfully applying the principles of physics—absorbing kinetic energy, extending impact duration, and distributing forces—they prevent catastrophic damage, ensure smooth operations, and protect billions of dollars worth of assets. As unsung heroes of the maritime world, rubber fenders make modern global trade and shipping safer and more efficient for everyone.